Thermo-Compression Molding of a Non-Woven Polyester Acoustic Duct for the Automotive Industry

At S&A Industries, we’re a leader in custom thermo-compression molding services. We were recently contracted by a customer in the automotive industry to fabricate a porous noise reduction duct. This duct was to be used in air induction systems on the dirty air side. This product featured an embedded hydrophobic resin, which prevents water intrusion with no negative impact to NVH.

To create this custom duct, we used a non-woven material, our thermo- compression expertise, and our superior assembly services. Hydrophobic, temperature resistant polyester was used for its lighter weight than a molded plastic counterpart. The complex assembly of the duct with plastic components assembled to the air filter box interface exhibited to our customer that our experience and knowledge extends beyond thermo-compression molding and allows us to work on projects from inception to completion.

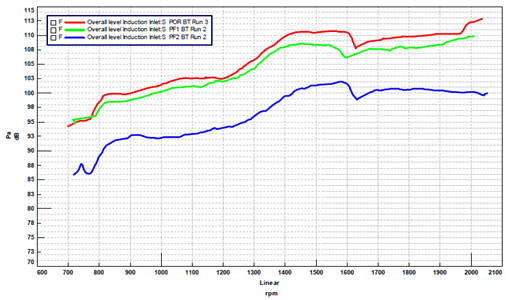

In the end, the porous duct yielded 10 dB improvement compared to a plastic duct and met the established underhood requirements. To learn more about this project our other capabilities contact us directly.

.

Thermo-Compression Molding of a Porous Noise Reduction Duct Project

| Thermo-Compression Molding |

| |

| Capabilities Applied/Processes |

| |

| 3D & Modeling capability | Software Capabilities :

| |

| Material Used | Non-Woven Polyester | |

| Technical Specifications |

| |

| Features / Advantage |

| |

| Noise Performance | Porous Duct yields 10 dB improvement compare to a plastic duct | |

| Industry for Use | Automotive - Air Intake Application on the dirty Side | |

| Delivery Location | Global | |

| Standards Met | Under hood requirement | |

| Product Name | Porous Noise Reduction Duct | |