Compression Molding of a Non-Woven Porous Air Intake System Duct for the Automotive Industry

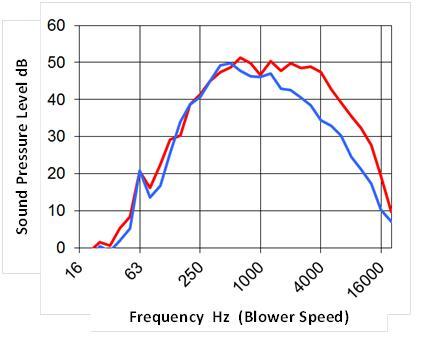

S&A Industries manufactured a porous, air-intake system (AIS), noise-reduction duct that meets automotive environmental and engine compartment requirements. The non-woven, compression-molded, recyclable polyester used in the duct reduces engine noise. Permeability can be adjusted to change its acoustic performance and it offers excellent temperature resistance. The porous part also weighed less than a molded plastic part and featured a water drain valve and is hydrophobic treated.

The duct was created using highly specialized software, such as LAMPS/SAPY for noise, SCRYU/Fluent for pressure drop and NX Unigraphics for design. We diligently tested and validated the parts and offered global delivery. For more information, please contact us directly.

Compression Molding of a Non-Woven Porous Air Intake System Duct Project Highlights

| Product Description | A compression molded fiber material is used for automotive air intake systems to attenuate noise propagated from the engine. | |

|---|---|---|

| Capabilities Applied/Processes |

| |

| 3D & Modeling capability | Software Utilized:

| |

| Material Used | Non-Woven Polyester | |

| Technical Specifications |

| |

| Features / Advantage |

| |

| Noise Performance |  | |

| Industry for Use | Automotive | |

| Delivery Location | Globally | |

| Standards Met | Automotive Environmental and Engine Compartment requirements | |

| Product Name | Porous Air Intake System (AIS) Noise Reduction Duct | |