Compression Molding of a Non-Woven Porous HVAC Duct for the Automotive Industry

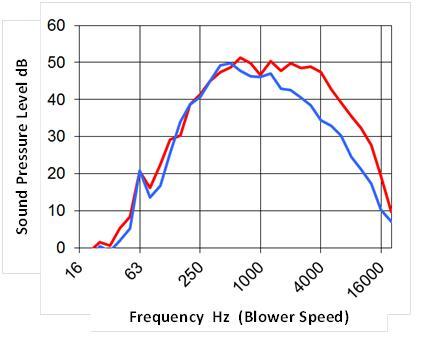

S&A Industries developed this thermo-compression molded, non-woven, porous duct that reduces noise in an automotive HVAC system. The duct, which was designed to reduce the air flow imbalance between inlet and outlet openings, offered a 9 dB improvement from 1000 Hz to 16000 Hz (max blower speed at 12V) to the full blower speed. We used highly specialized software, such as LAMPS/SAPY for noise, SCRYU/Fluent for pressure drop and UG/NX for design to create and model the duct. The porous non-woven polyester used in this S&A duct is 35% lighter than a comparable, 2.5 mm-thick plastic blow-molded duct. The part improved the pressure drop by 10% at 65 cfm and met the standards for automotive interiors. Please see below or contact us directly for more information.

Compression Molding of a Non-Woven Porous HVAC Duct Project Highlights

| Product Description | Compression Porous duct is used for noise reduction within a HVAC system of an automobile. | |

|---|---|---|

| Capabilities Applied/Processes |

| |

| 3D & Modeling capability | Software Utilized:

| |

| Material Used | Non-Woven Polyester | |

| Technical Specifications |

| |

| Features / Advantage |

| |

| Noise Performance | 9 dB improvement from 1000 Hz to 16000 Hz full blower speed

| |

| Industry for Use | Automotive (Interior HVAC Duct) | |

| Delivery Location | North America | |

| Standards Met | Automotive Interior requirements | |

| Product Name | Porous Console Blower Duct | |